Natural gas typically contains a large amount of water, especially when produced from a reservoir. This can cause problems such as:

- Increase in pressure drop, which can result in slug flow

- Freeze or form solid hydrates that reduce gas flow or plug the line

- Enable acidic gases like Hydrogen Sulfide or Carbon Dioxide to dissolve in the water and corrode components

- Allow condensate to form and cause compressors to break or fail

To avoid these problems, glycol is pumped into a system to serve as a liquid desiccant and remove the water. Triethylene Glycol (TEG) is used most often. Diethylene Glycol (DEG), Ethylene Glycol (MEG), and Tetraethylene Glycol (TREG) are also used.

Hydra-Cell Gas Drying Pump Models

Hydra-Cell offers a wide range of models to meet individual flow and pressure requirements. Click below to see our selection.

F/M/D/H Series Pumps

F/M/D/H Series Pumps

For maximum flow rates up to 65.7 gpm (248.7 l/min)

Q Series Pumps

Q Series Pumps

For maximum flow rates up to 157 gpm (595 l/min)

Hydra-Cell Performance Advantages Compared to Other Types of Pumping Technologies

- Seal-less design means no packing to leak, replace, or adjust. There is less downtime, less environmental containment costs, and less annual maintenance compared to conventional plunger pumps.

- No mechanical seals to fail, leak, or replace.

- Can pump water-thin fluids without having to adjust the pump speed. The required flow is delivered due to very low slip rates.

- Does not require the pumped fluid for lubrication – no loss of glycol.

- Accurate control of flow rate by varying pump speed over a wide range of discharge pressures and fluid viscosities.

- Handles sand or other solids up to 800 microns in size (depending on pump model). No fine filtration is required.

- Can run dry indefinitely; the pump does not use the process fluid for lubrication.

- Higher volumetric efficiency than gear pumps when pumping low-viscosity fluids.

- Alternative materials available for the manifold, valves, and diaphragms if hydrogen sulfide (H2S) is present.

- Hydraulically balanced diaphragm design for long life.

- Patented diaphragm position control technology enables operation and protects the pump in case of a closed inlet due to abnormal or adverse conditions, or operational error.

- Rugged construction for long life with minimal maintenance.

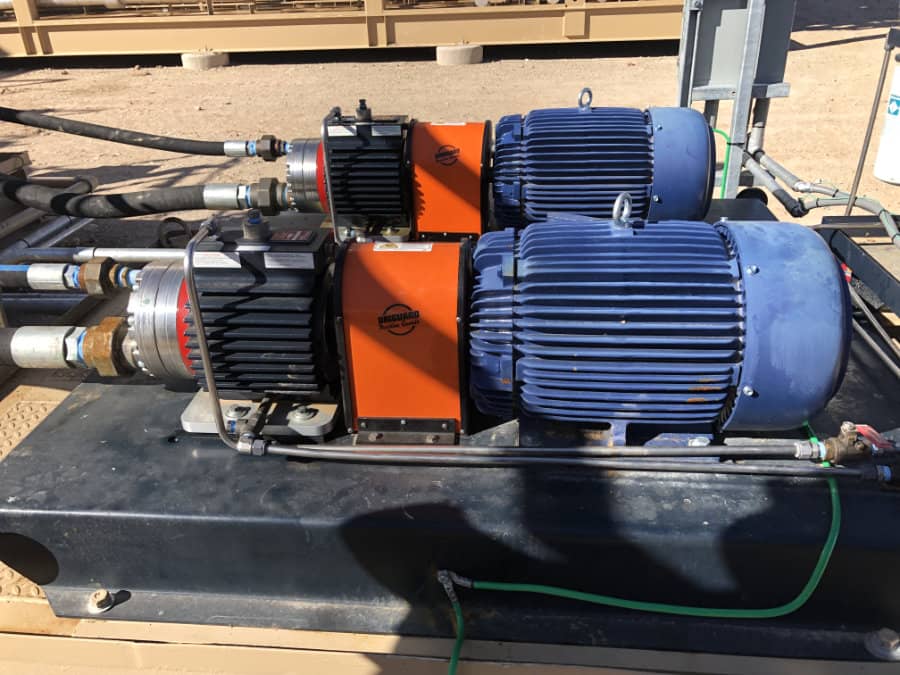

- Compact direct drive skid designs for a smaller installation footprint.

- Oil coolers available for fluid temperatures above 160 F.

Download the Brochure

Download the Brochure

Reliable Pumps for Oil and Gas Processing

We're in your industry - Please contact us for help!